QUALITY

QUALITY AT NORMSAN

NORMSAN manufactures high quality aluminum and zamak parts for its customers. Our company has ISO 9001: 2015 Quality Certificate.

We implement a meticulous product quality planning system for the purposes of improving process failure mode and impact analysis (PFMEA) and quality products prior to initial sample submission.

Critical and sensitive products are kept subject to quality control in processes with SPC, Cpk, Ppk applications. We have a spectrometer device that ensures the safe control of raw material aluminum and zamak alloys.

Thanks to the sample polishing machine and the metal microscope, we have the capability of inspecting the casting internal quality and material structures.

QUALITY LABORATORY

High quality casting production requires the dedication of an experienced and knowledgeable quality control department. To achieve this goal, NORMSAN continues to make significant laboratory investments to enable the company’s quality control technicians to perform process controls.

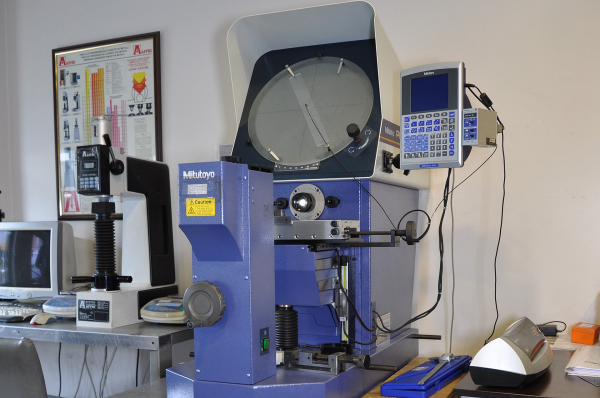

NORMSAN’s quality control technicians use spectrometers, metal microscopes, profile projection device, permeability devices, surface roughness test devices, hardness measurement devices etc. in order to provide the highest quality manufacturing as normal complement to the inspection / evaluation equipment available in manufacturing environments.

- Spectrometer

- Surface Roughness Measurement Device

- Sample Polishing Device

- Metal Microscope

- Profile Projection Device

- Granite Plate

- Roughness Measurement Device

- Permeability Test Device

İstanbul Anadolu Yakası

Org. San. Bölgesi Gazi Bulvarı

No:47 34953 Aydınlı

TUZLA / İSTANBUL